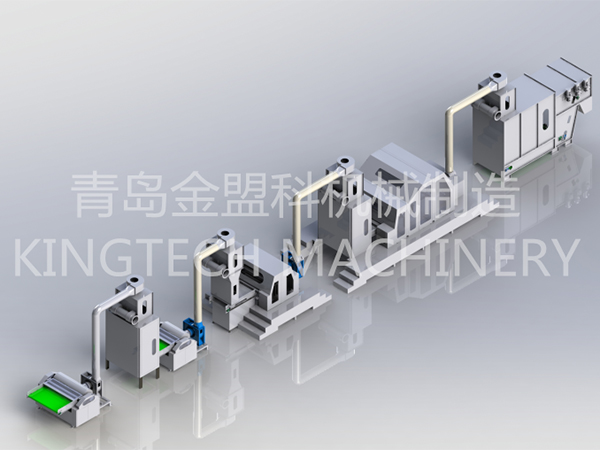

Kingtech-Opening Carding System

Spunlace and Air-Through Cloth Solution

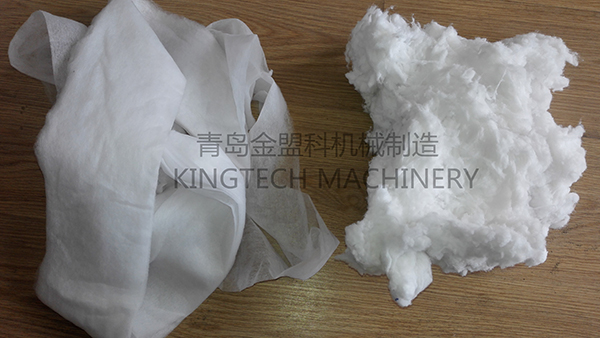

Input Material

Output Material

Unique Design Of Recycling Solution For Processing Irregular Spunlace and Air-Through Cloth Edge Trim Waste. Output Fiber is free from any neps, very good Fiber Effect Suitable For making Spunalce and Air-Through Cloth Again.

Hemp/Jute Solution

Input and Output Material

Full Stainless Steel

Long Fiber Length

Aramid/Kevlar Solution

Input and Output Material

Cotton Yarn Waste Solution

Input and Output Material

Polyester Yarn Waste Solution

Input and Output Material

Wool Sweater Solution

High Production With Very Fine Fiber Output.

Please check the Video attached.

Other Information

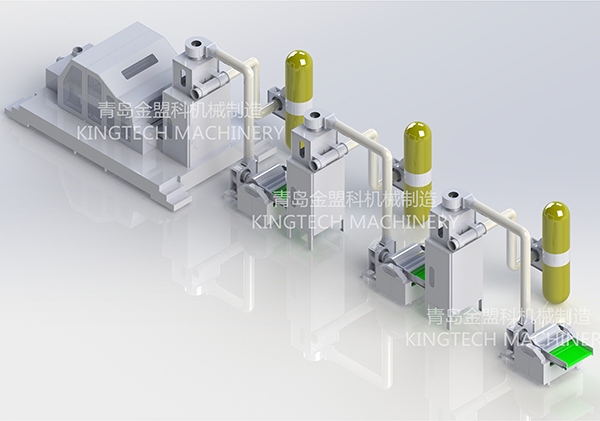

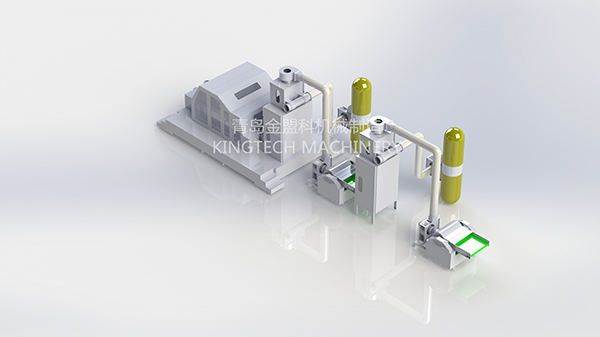

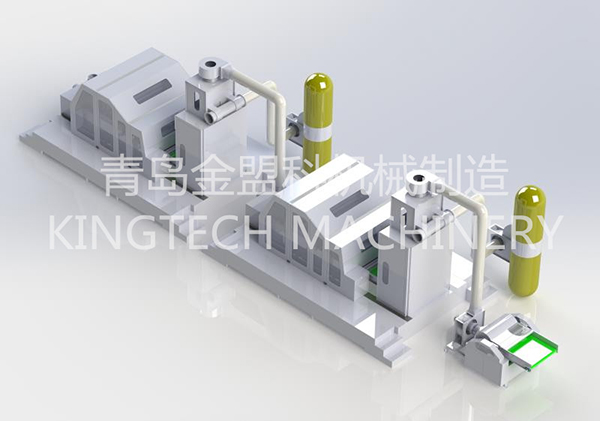

Customer will face a Situation that Disordered Waste Fabric cannot be Completely Processed by Traditional Solution, Small Pieces or Non-opened Fiber might appear in the Output Fiber. When Customer ask for High Quality Fiber, that prove to be Difficult by Old Model Solution. The Fiber Length will decrease if More Processing Units are Required, in this Way we Roll out New Design Opening-Carding System, Especially For Spunlace and Air-Through Cloth Maker. They have Material in Roll Form, but most of them are un-Rolled/Disordered Condition, Before us, there is no Machine in the Market suitable for processing.

Opener and Carding System, Working Width 1000mm / 1500mm / 2500mm

Big Cylinder With Workers Around, more Effective Fiber Combing

Based on Different Situation, Machine Group can be One/Two/Three Openers + One/Two Carding Machine.

Already Work For Spunlace / Air Through Fabric, also include Wool Material / Waste Yarn / Hemp(Jute) Etc.